Overview

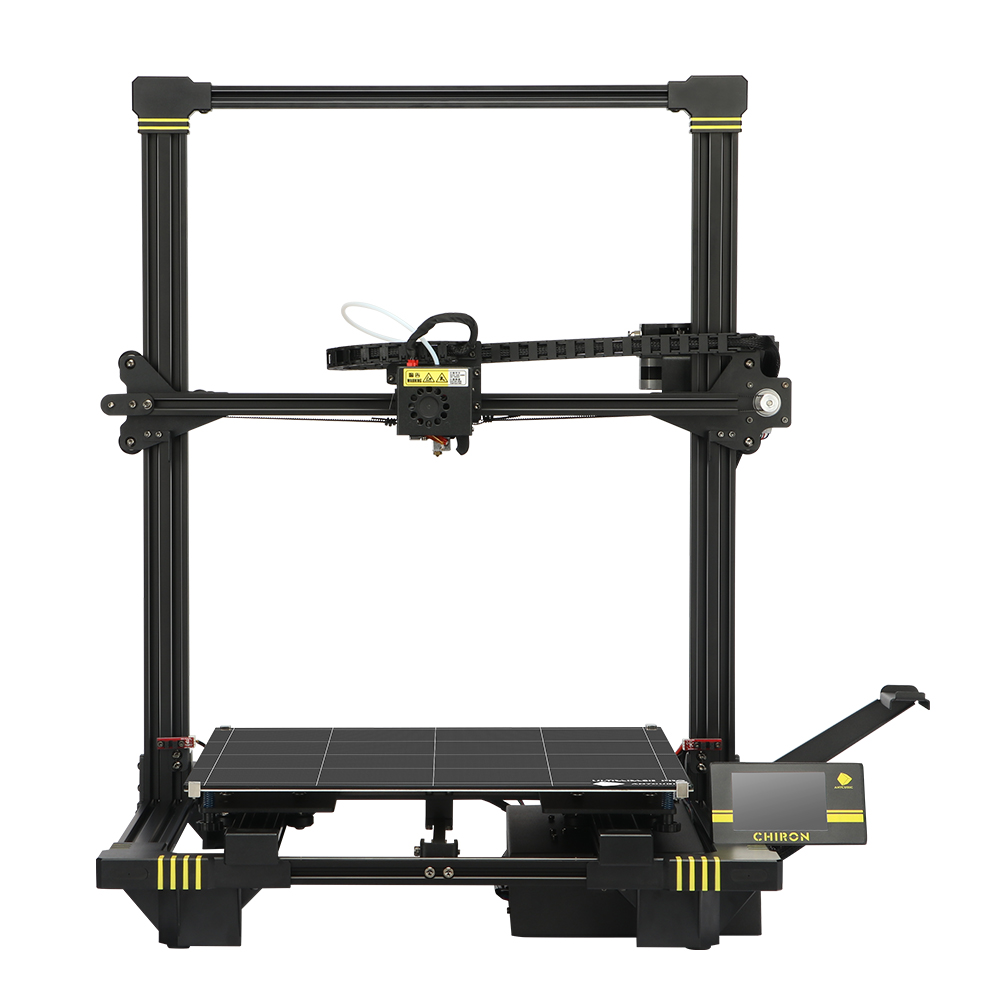

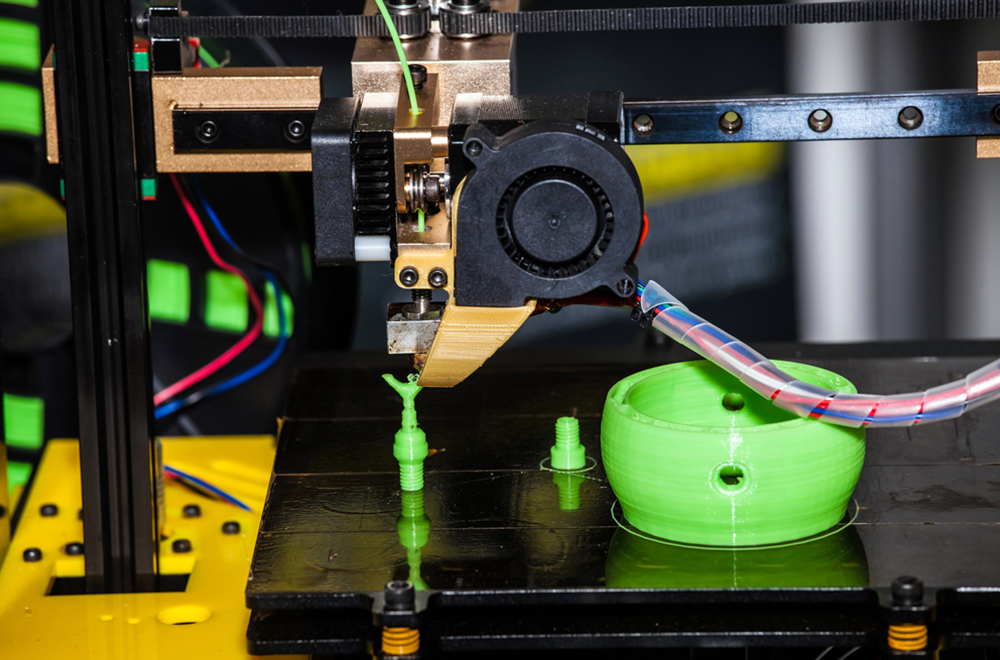

Chiron Anycubic is an incredible, smart, convenient and powerful FDM 3D printer perfect for manufacturers and professional use. It has a huge printing volume of 400*400*450mm for a greater variety of printed products, an Ultrabase pro, and a powerful heatbed and new design auto-leveling technology to guarantee high quality and smooth printing. It is easy to operate with a TFT touch screen and it resumes printing from accidental power loss to ensure there is no waste of filament and time. It is surely a very high-quality product that guarantees results with it’s super precise and detailed printing of 0.05-0.3 mm. Compatible with a wide variety of filament makes this 3D printer a magnificent machine in the world of professional manufacturing.

Key features

-

Quick assembly

- Quick assembly and modular design lets you begin printing right away

-

-

Fast printing and big size

- This 3D printer has a printing speed of 20-100 mm/s and a huge printing volume of 400*400*450mm

-

-

Stable Structure

- Photoelectric Dual Z Axis limit switch offers more stable leveling of the print bed. The matrix automatic leveling detects 25 points, supports real-time compensation of nozzle height, real-time adjustment

-

-

Highly accurate

- Chiron has a titan extruder, which makes printing that much better and precise. The precision of this 3D printer is 0.05-0.3 mm, which make sit a perfect choice for various fields, such as dental industry, architectural designs, industrial products, prototypes and so on

-

-

Operation Method

- TFT touch screen LCD screen and control button make this printer easy and convenient to use

-

-

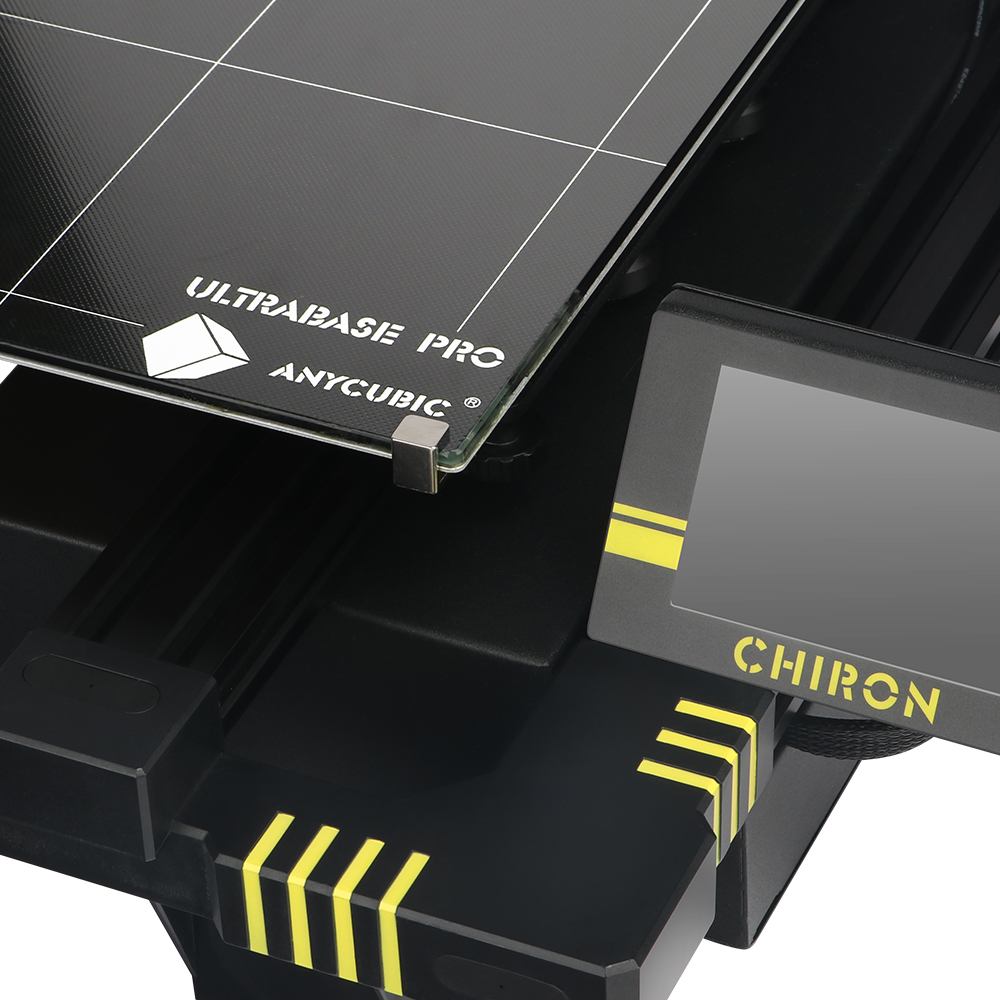

Heatbed

- Ultrabase pro and high-powered heatbed guarantee flawless printing of any product

-

Dimensions

Printing Size

Area Length

Area Width

Height

Box Dimensions

Length

Width

Height

Box Weight

Kit includes

- M5x25 screw/washer x6

- Filament holder x1

- (M3*5, M4*8, T-nuts x2 each)

- Filament x1

- User Manual

- Leveling sensor Kit

- Power cord x1

- Data Cable x1

- Gloves x2

- Memory card & Card reader x1

- Tool Kit (Screwdriver, hexon wrench)

- Extra Print head

- Tweezers & nozzle cleaning needles x1

- Spatula x1

Specifications

| Technology

FDM (Fused Deposition Modeling) |

Build Size

400 x 380 x 450 (mm³) |

Layer Resolution

0.05-0.3 mm |

| Positioning Accuracy

X/Y 0.0125mm, Z 0.002mm |

Extruder Quantity

Single |

Nozzle Diameter

0.4 mm |

| Print Speed

20-100mm/s (suggested 60mm/s) |

Travel Speed

60mm/s |

Supported Materials

PLA, ABS, TPU, HIPS, Wood |

| Input rating

110V/220V AC, 50/60Hz |

Slicer Software

Cura, Smplify3D, Repetier-HOST |

Input Formats

.STL, .OBJ, JPG, PNG |

| Output Formats

GCODE |

Connectivity

SD card; Data cable (expert users only) |

Printer Dimensions

651mm x 612mm x 720mm |

| Ambient Operating Temperature

8°C – 40°C |

Operational Extruder Temperature

max 260°C |

Operational Print Bed Temperature

max 100°C |

| Net Weight

~20kg |

|

CERTIFICATES

Related Products

FAQ

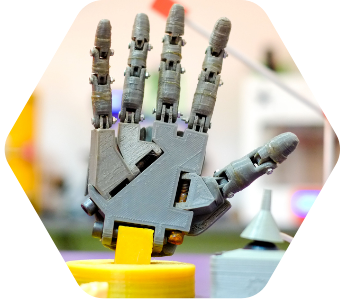

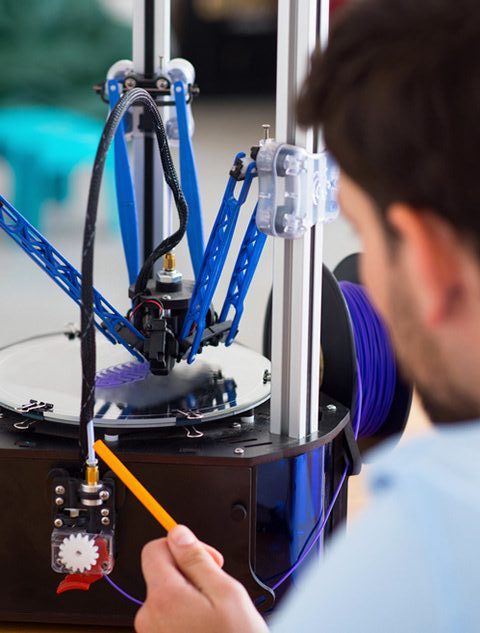

Additive manufacturing or 3D printing is the technology where a three-dimensional object is being printed, layer by layer from a CAD model. Each 3D printer operates with special software, and the 3D models to print can be either downloaded or designed.

There are many different ways to carry out the printing process itself. The main distinctive feature between different printers and technologies is the thickness layer - the thinner the layer, the better and smoother the end product. The difference may be between a couple of millimetres to a couple of microns.

There are many areas of use for a 3D printer, from creating a home decore to education and industries. When it comes to industries, a 3D printer can innovate the production process of individual parts, bringing new materials to light and lifting the level of quality.

3D printers can easily be used by tech-fans, people who like building models, cars, aeroplanes, and others, and also by those who see it as a fun hobby. Most intricate models, the smallest parts, and complicated shapes can be printed.

Many various 3D printing processes exist. The first one ever created was SLA. However, the most commonly used one today, especially for educational and home use purposes as a desktop printer is the FDM (Fused Deposition Modeling). They are comparatively cheap and easy to use, hence their overwhelming popularity.

The most commonly used materials are plastics that include PETG, ABS, and PLA. Of course, many other materials can be used in 3D printing with FDM technology; however, their use depends on the printer itself and its ability to process them.

Review

Customer Reviews

(52 Reviews)

Reviews Would recommed this product

Overall rating totals