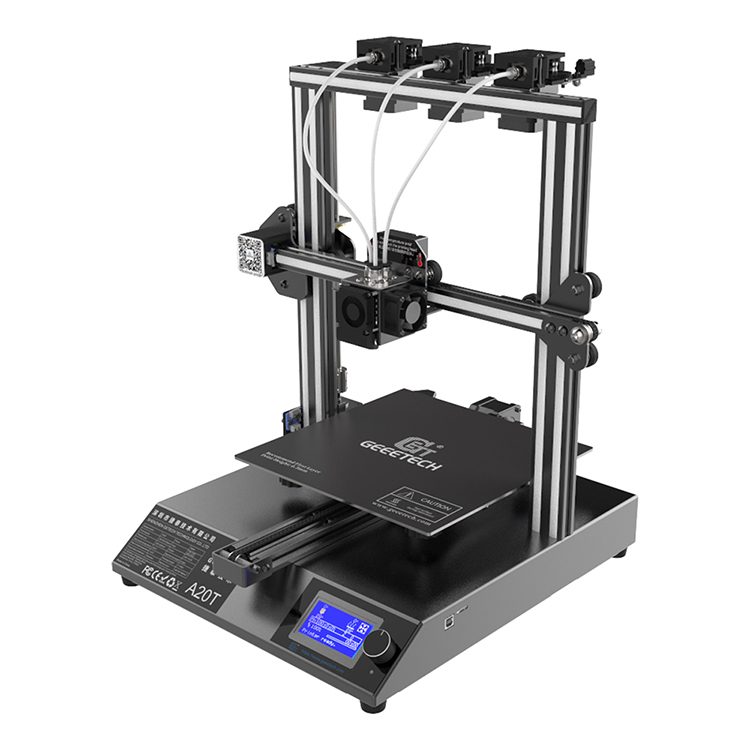

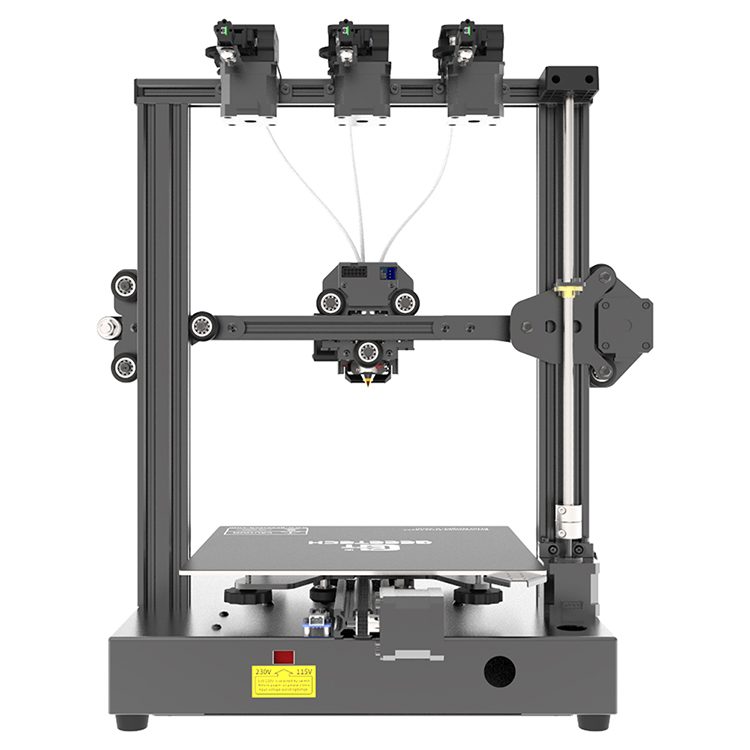

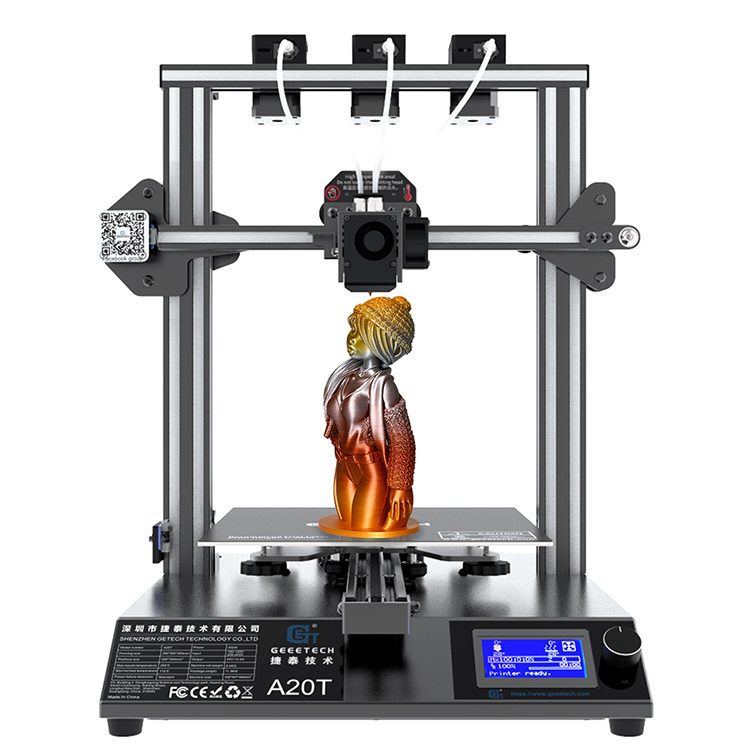

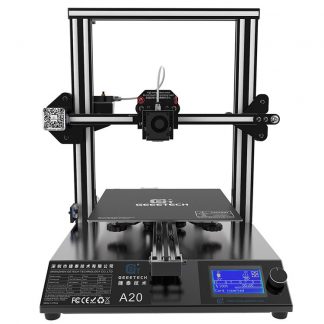

Geeetech A20T 3D Printer

£ 450 .00

KEY FEATURES

- Build Volume: 250*250*250

- Software: Repetier-Host, EasyPrint 3D, Cura

- Printing technology: FDM

- Filament: PLA, ABS

- Nozzle diameter: 0.4 mm

- Printing accuracy: 0.1 - 0.2 mm

- Screen: LCD display

If you buy this product 30% of the profit will be donated to Eworld Kids Foundation

Overview

Geeetech A20T, the best professional 3D printer, is a bright example of a quality device with sturdy construction. It performs with high accuracy and precision to bring you the best printing experience. This printer is capable of combining three colours in one print, which broadens the horizons of creativity and sets a high bar for 3D models. Geeetech A20T has a printing size of 250-250-250mm, so it will be most helpful for individual use, for printing household items, miniatures, all sorts of models from dental to architectural. This device will fit into any learning environment, from junior highs to universities. It supports a range of filaments like PLA, ABS, PVA, HIPS, etc. It is adjusted to fit multiple operating systems, such as Windows, Linux and Mac, and has the option to work offline, using either a USB port or a card slot. The extruder and the nozzle are built to dissipate the heat properly and have all-around ventilation in order to avoid leaks and keep the extruder safe from overheating.

Key features

-

Mix-colour printing

- This is a huge advantage not only for printing toys but frankly for making the whole printing experience more vibrant and fun.

-

-

Filament sensor

- This Geeetech 3D printer will signal if there’s a break in the filament flow, or if it ran out, stopping the printing.

-

-

Break-resume capability

- In case the power source is not very reliable, this feature is a lifesaver. It will allow you to resume printing from the last point, instead of wasting time and filament on redoing the whole model.

-

-

Auto-levelling optional add-on

- Manual levelling takes quite a lot of skill and time, so this add-on might come in handy. It will level the bed perfectly for smooth surfaces and clean results.

-

-

Upgraded gear train

- The extruder motor amplifies the input torque to make the printing process seamless.

-

-

Easy assembly

- The device is quite easy to put together, it takes only a few steps to achieve the desired result!

-

Dimensions

Printing Size

Area Length

Area Width

Height

Box Dimensions

Length

Width

Height

Box Weight

Kit includes

- Gantry Kit

- Bottom Kit

- Extrduer Motors (3 sets)

- Filament Detector Kit (3 sets)

- Machine Installing Screws

- Power Cord

- TF Card

- Tool Kit

- USB Cable

- Nozzles x2

- Filament

- Mouse Pad

- Teflon Tube & Zip Ties

- User Guide

Specifications

| Printing Technology

FDM |

Hot bed maximum temperatue

110° C |

Printing Volume

250*250*250 m³ |

| Nozzle diameter

0.4mm |

Printing accuracy

0.1~0.2 mm |

Filament

Diameter 1.75mm; ABS/PLA,etc. |

| Position precision

x/y: 0.011 mm z:0.0025 mm |

Environment temperature

10°C-40° C |

Printing speed

60mm/s |

| Operating system

Windwos/ Mac/ Linux |

Nozzle quantity

3-in-1-out single nozzle |

Slicing software

Repetier-Host, EasyPrint 3D, Cura |

| Extrusion head maimum temperature

250° C |

File format

STL/.Gcode |

Power input

100-120V/200-240V |

| Connectivity

TF card, USB |

Power output

DC24V/14.6A, 350W |

LCD screen

LCD 12864 screen |

| Printer size

442x447x480 mm³ |

Net weight

~ 9 kg |

Package size

510x495x305 mm³ |

| Gross weight

~ 9 kg |

CERTIFICATES

Related Products

FAQ

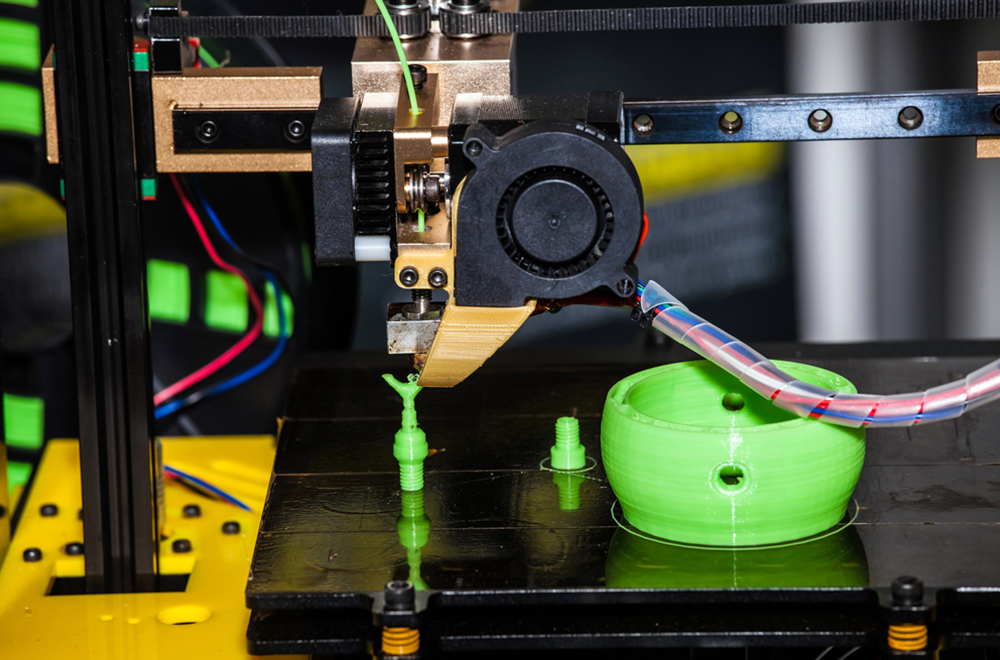

Additive manufacturing or 3D printing is the technology where a three-dimensional object is being printed, layer by layer from a CAD model. Each 3D printer operates with special software, and the 3D models to print can be either downloaded or designed.

There are many different ways to carry out the printing process itself. The main distinctive feature between different printers and technologies is the thickness layer - the thinner the layer, the better and smoother the end product. The difference may be between a couple of millimetres to a couple of microns.

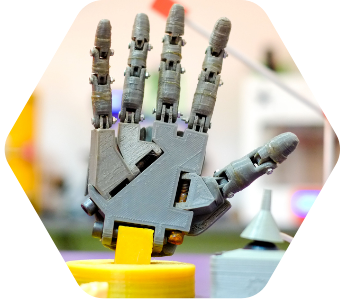

There are many areas of use for a 3D printer, from creating a home decore to education and industries. When it comes to industries, a 3D printer can innovate the production process of individual parts, bringing new materials to light and lifting the level of quality.

3D printers can easily be used by tech-fans, people who like building models, cars, aeroplanes, and others, and also by those who see it as a fun hobby. Most intricate models, the smallest parts, and complicated shapes can be printed.

Many various 3D printing processes exist. The first one ever created was SLA. However, the most commonly used one today, especially for educational and home use purposes as a desktop printer is the FDM (Fused Deposition Modeling). They are comparatively cheap and easy to use, hence their overwhelming popularity.

The most commonly used materials are plastics that include PETG, ABS, and PLA. Of course, many other materials can be used in 3D printing with FDM technology; however, their use depends on the printer itself and its ability to process them.

Review

Customer Reviews

(138 Reviews)

Reviews Would recommed this product

Overall rating totals

Reviews (138) Write a Review

crac.armenia@gmail.com 2024/1/24

Hamlet Martirosyan

sdfsd

MAXIM SAUNDERS 2024/1/22

The printer was easy to assemble and configure. I am new to 3D printing, but not to electronics, computers, and computer aided design. And i can say this is really a good printer.

Noah B. 2024/1/22

For the record I have to say that my first 3D printer was the Anet A8. Naturally, being a budget printer it had a lot of downsides, but once I got the Geeetech A20T, I realized, that although it's roughly in the same price category, the Geeetech would have given me the opportunity for more upgrades and for less money.