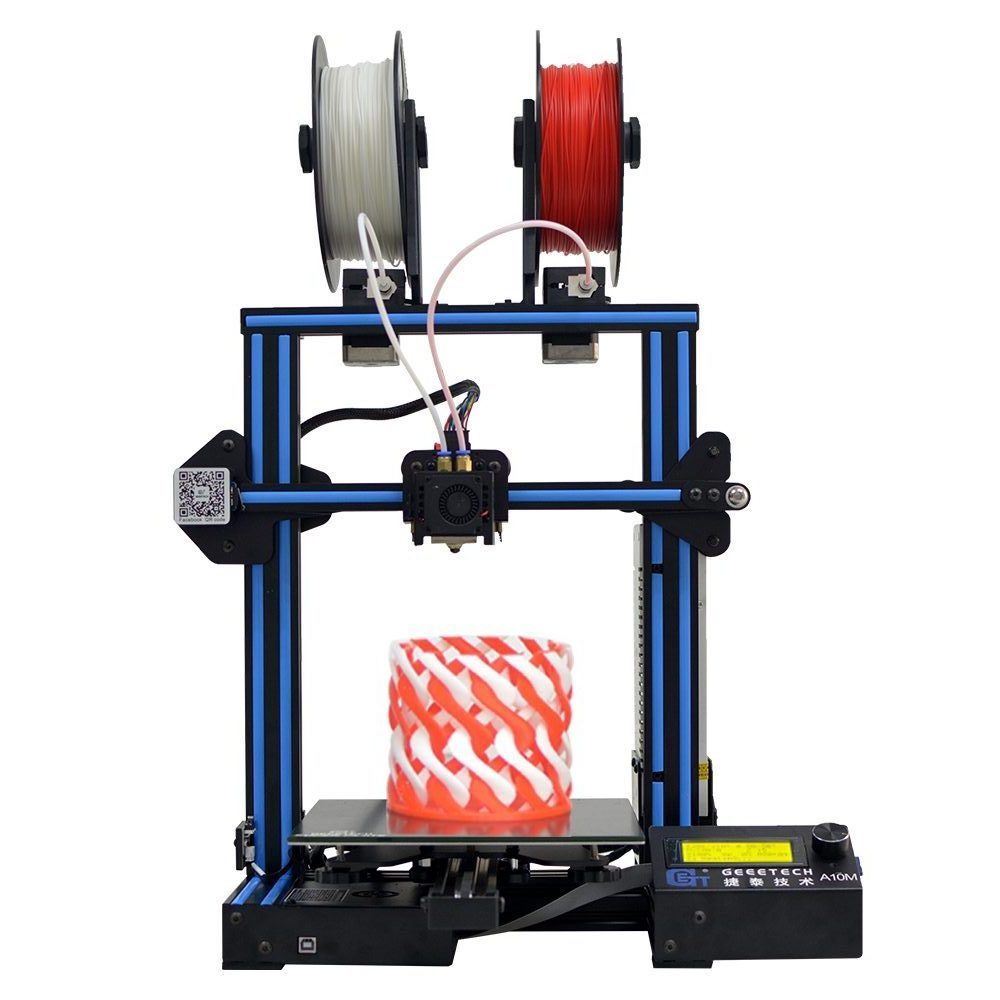

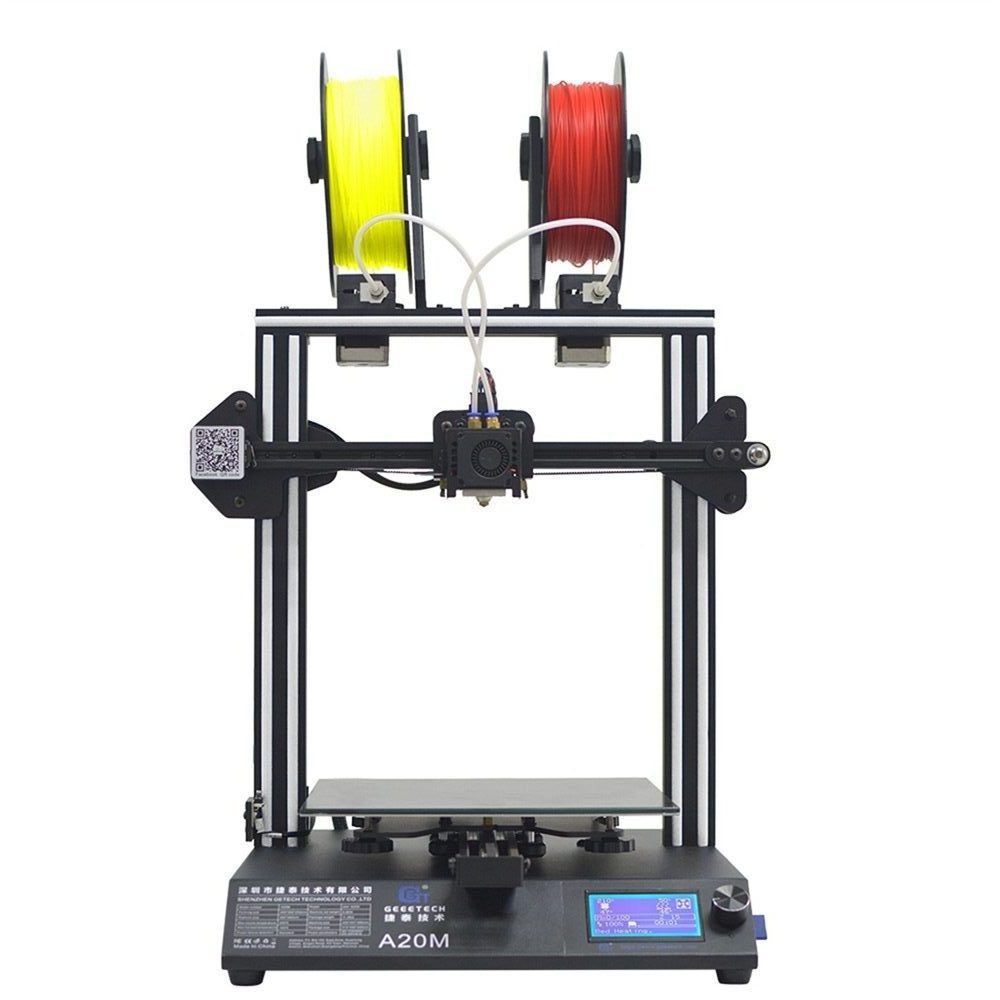

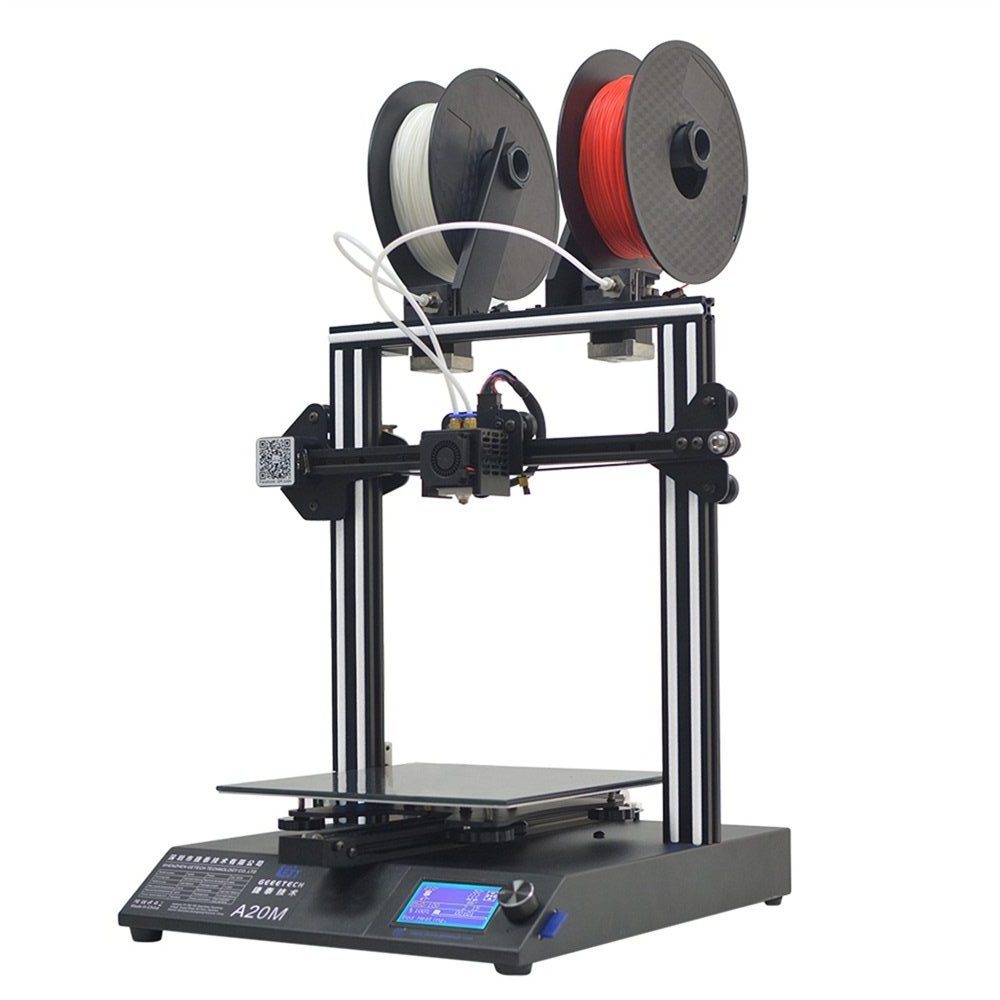

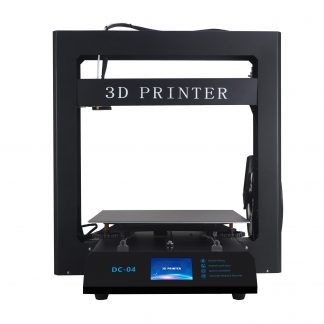

Geeetech A20M 3D Printer

£ 380 .00

KEY FEATURES

- Build Volume: 255*255*255

- Software: Slic3r, Cura, Simplify3D, Repetier

- Frame: Aluminium

- Printing speed: 60 mm/h

- Nozzle diameter: 0.4 mm

- Printing accuracy: 0.1 - 0.2 mm

- Printing: mixed color

If you buy this product 30% of the profit will be donated to Eworld Kids Foundation

Overview

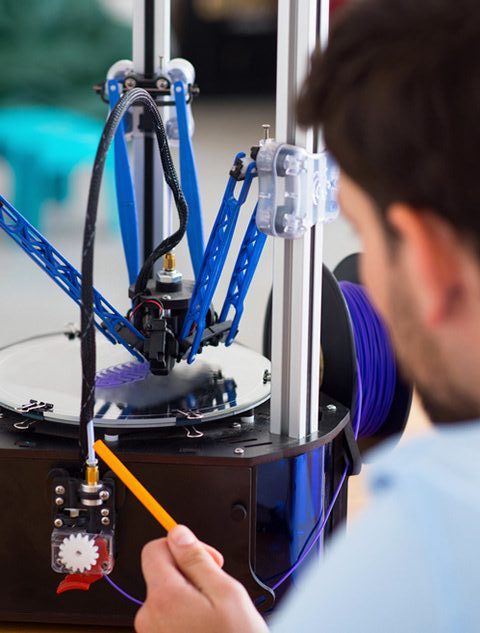

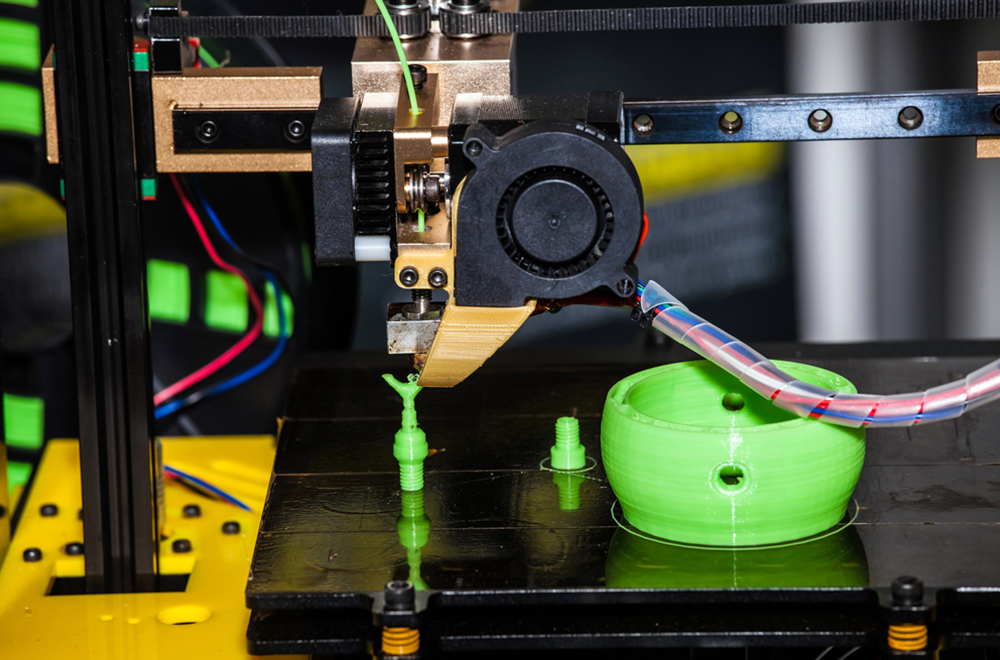

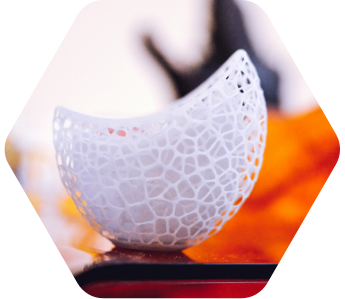

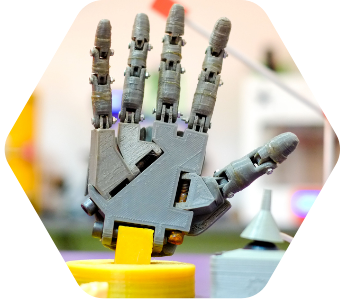

The Geeetech A20M 3D printer for home provides immaculate performance, demonstrating precision and high-quality printing. It is capable of printing in mixed colours, which adds vibrance and versatility to the printing experience. This device features a premium-quality extruder, built for higher accuracy and clean results. The extruder ensures amplified heat dissipation, which protects the extruder itself and the nozzle from overheating. With a printing size of 255-255-255mm, it can create different sorts of models, toys, household items, and much more, using various filaments like HIPS, PLA, ABS, Flexible PLA, etc. The unique design of wheels and rails ensures smooth motion, thus providing a better printing experience and less trouble. The Geeetech A20M will work with Windows, Linux and Mac so that no one will be left out.

Key features

-

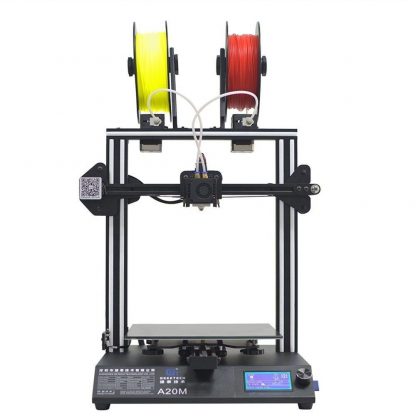

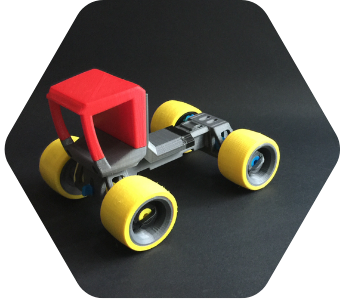

Mixed-colour printing

- This feature will definitely spark interest and make printing much more fun. It adds that extra pinch, especially for toy and miniature printing.

-

-

Extruder and nozzle

- They are both built with premium-quality materials with best printing experience in mind. Correct heat dissipation and nozzle precision guarantee the desired result.

-

-

V-shaped wheels

- The wheels and rails on the Geeetech A20M 3D printer are meant to minimise imperfections due to friction.

-

-

Open source control board

- This is an excellent source for learning and upgrading the device - more than a desirable feature for people who plan on exploring the 3D printing world further and installing upgrades to their existing devices.

-

-

USB and SD card slot

- They will both come in handy in different situations, so why choose one or the other when you can have both providing a convenient offline printing!

-

-

Filament detection

- The printer will let you know if there’s a glitch in the filament flow, or when it simply ran out. Thanks to this feature there won’t be damage to the model itself and the device will start right where it left off whenever the problem is eliminated.

-

Dimensions

Printing Size

Area Length

Area Width

Height

Box Dimensions

Length

Width

Height

Box Weight

Kit includes

- Extruder Motors x2

- Power Cord

- Filament Detector Kit x2

- Round Head Hexagon Screws M4*8mm x2

- Filament Holder Kit x2

- SD Card

- Hexagonal Socket Head Cap Screws M5*45mm x4

- Spring Washers M5 x4

- Tool Kit

- Mouse Pad

- Starter Filament

- USB Cable

- Zip Ties x20

- Ejection Pin x2

- Spare Nozzle

- Spare Nuts Kit

- Spare Teflon Tube x2

Specifications

| Build volume

255*255*255 mm³ |

Printing accuracy

0.1mm |

Printing speed

120 mm/s (max) |

| Filament diameter

1.75mm |

Nozzle diameter

0.4mm |

Filament

PLA, ABS, nylon, wood polymers, etc |

| Max temp for hotbed

100℃ |

Max temp for extruder

250℃ |

Operating system

Windows, MAC, Linux |

| Control software

Repetier-Host, Simplify 3D, Cura, Slic3r, etc. |

Remote App

EasyPrint 3D App (with an optional 3D WiFi module) |

File format

STL,OBJ,Gcode |

| Power supply

Input: 115V/230V Output: DC 24V, 15A |

Connectivity

Wi-Fi (with an optional 3D WiFi module), USB,sd card |

Display screen

LCD 12864 |

| Frame

Aluminum profile |

Machine Dimension

478 x 413 x 485mm³ |

Shipping box Dimension

500 x 470 x310 mm³ |

| Machine Net weight

7.6kg |

Machine Gross weight

9.45 kg |

Build Platform

Sticker with aluminum Platform |

CERTIFICATES

Related Products

FAQ

Additive manufacturing or 3D printing is the technology where a three-dimensional object is being printed, layer by layer from a CAD model. Each 3D printer operates with special software, and the 3D models to print can be either downloaded or designed.

There are many different ways to carry out the printing process itself. The main distinctive feature between different printers and technologies is the thickness layer - the thinner the layer, the better and smoother the end product. The difference may be between a couple of millimetres to a couple of microns.

There are many areas of use for a 3D printer, from creating a home decore to education and industries. When it comes to industries, a 3D printer can innovate the production process of individual parts, bringing new materials to light and lifting the level of quality.

3D printers can easily be used by tech-fans, people who like building models, cars, aeroplanes, and others, and also by those who see it as a fun hobby. Most intricate models, the smallest parts, and complicated shapes can be printed.

Many various 3D printing processes exist. The first one ever created was SLA. However, the most commonly used one today, especially for educational and home use purposes as a desktop printer is the FDM (Fused Deposition Modeling). They are comparatively cheap and easy to use, hence their overwhelming popularity.

The most commonly used materials are plastics that include PETG, ABS, and PLA. Of course, many other materials can be used in 3D printing with FDM technology; however, their use depends on the printer itself and its ability to process them.

Review

Customer Reviews

(78 Reviews)

Reviews Would recommed this product

Overall rating totals

Reviews (78) Write a Review

Michael M. 2024/4/14

This printer is actually almost completely ready to go. Just attach the base to the frame and two extruders to the spool holders. I managed to put the whole thing together in less than half an hour.

Louis G. 2024/4/13

First of all, this printer has the power supply and the motherboard underneath the platform rather than next to it, which was much more convenient for me. The printer was generally easy to assemble and didn't require to square up and meddle with the lower frame.

Ewan O. 2024/4/10

I wanted to get the Geeetech A20M mainly to compare it with the A10M I already have, and I have to say, the A20M has lots of cool features. like a bigger display and the overall printing experience is a bit smoother