Table of Content

Introduction

Origin and History of 3D Printing

Benefits of 3D Printing

3D Printing Technology

3D Printing Process

3D Printers and Types

3D Modeling Process

3D Printing Accessories: Filament and 3D Pen

3D Printing Apps

Applications of 3D Printing

How to Choose a 3D Printer

Why You Should Choose Us

To Sum Up

In this article, you will learn anything you need to know about 3D printing, from history to technology. Plus, you will learn what 3D printers are used for and what you can make with them at home.

Introduction

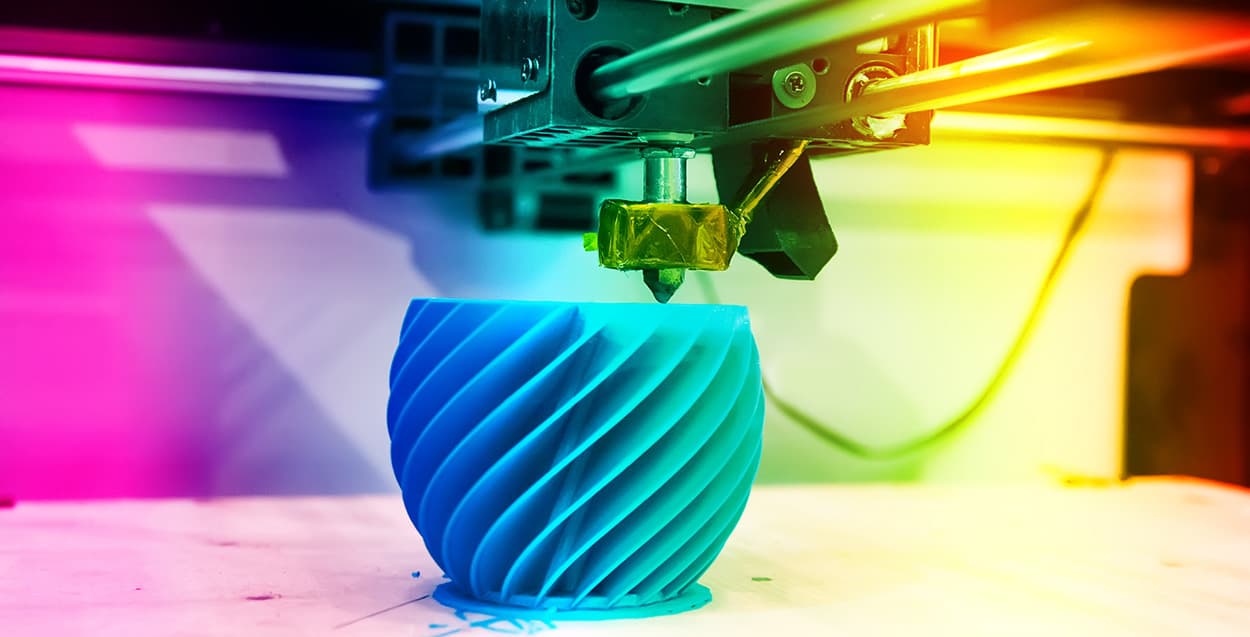

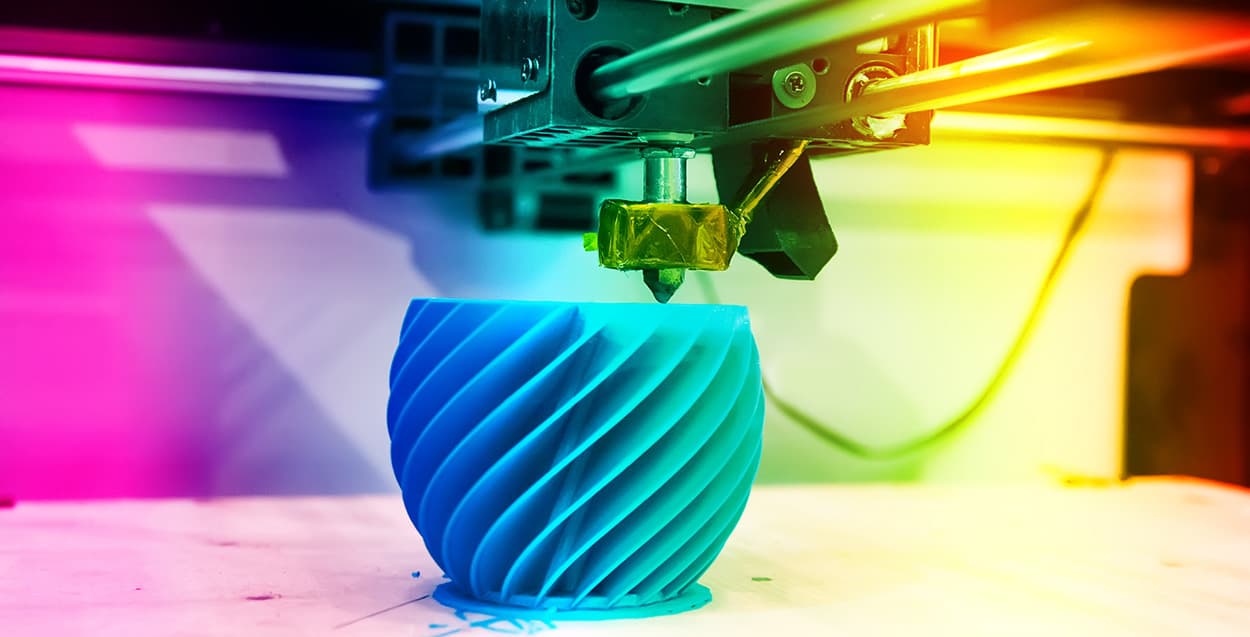

3D printing is a fairly new technology and idea, but it has already heavily infiltrated our lives and the industrial world. From aviation and automotive to clothes and home design – there are lots of things that are created using this very technology.

There are a lot of reasons why it has found such widespread use. With a 3D printer, the manufacturing is much faster, sometimes cheaper. Plus, it helps to eliminate huge machines and automate some processes that are heavily reliant on humans.

But what is a 3D printer, and how can a person use it at home? Why would anyone even want to get such a complicated piece of what seems like a machine from the future?

Let us walk you through the process, starting from the very beginning.

Origin and History of 3D Printing Industry

What is a 3D printer?

Additive manufacturing or 3D printing is the process of creating multidimensional objects from a digital 3D model or a CAD model.

It was first introduced quite recently in terms of historical timelines, only 40 years ago. The first 3D printer was built in the early 1980s, whereas the concept of this technology was first introduced a few years earlier.

The first-ever 3D printer was built in 1983 by Chuck Hull, which used a UV laser to build object layer after layer out of liquid raisin. This method is known as Stereolithography or simply SLA.

In the following years, many various technologies were created in order to help people with different needs, using a wide variety of materials.

Benefits of 3D Printing

This technology has very significant and, in some cases, revolutionary benefits that it can bring to big companies across many fields as well as to those who are just starting their business.

3D printing is widely used not only in prototyping but also in the full production lines of many manufacturing businesses. Some are also switching to 3D technology from the traditional means of production.

Here is the list of the main benefits from the latest 3D printing technology:

- Cost Reduction – probably the most important benefit when it comes to profitability, as you can still meet all your objectives and demands, but at a lower cost.

- Various Materials – there is a wide variety of different materials that can be used in 3D printing technology, and the list of those materials is rapidly growing. Plus, you can experiment and test different materials for innovation purposes.

- On-Demand Manufacturing – you can create a different product when they are needed, instead of overloading your warehouses.

- Fast Production – Traditional production methods take a long time to set up. However, the best 3D printing technology takes much less time. Plus, the production process is much faster, and the bugs are much easier to detect and fix.

- Idea- Prototype – The development of an idea into a prototype used to take ages, now it’s much quicker, and bugs can be fixed along the way. Sometimes it takes a ready product to see flaws in the design, which are much easier to fix in the digital model and try again.

The whole idea behind using 3D printing technology for business is that you are able to create a new and quality product faster than your competitors. With this technology, the time between idea, design and testing is much shorter, the process is much cheaper, and the flaws are easily detectable and fixable.

That’s the main reason why more and more companies are choosing to switch over to this method – in order to survive and get ahead in the times of fierce competition in the high-tech world of today.

3D Printing Technology

As we have already mentioned, there are many different methods or technologies used in 3D printing that can help you accomplish different goals, use different printing methods and materials and vary in their printing speeds.

Refer to the list below to see them all and know which ones are best for your needs:

As stated above, this one is the oldest method of 3D printing technology and it uses a liquid resin that is hardened by the UV ray into the desired shape layer by layer.

- Fused Deposition Modeling (FDM)

This method is most commonly used for commercial production and 3D printers for the general public. Here, a plastic filament builds the object on a heatbed while it gets heated and goes out through an extruder.

- Selective Laser Sintering (SLS)

This method is much like SLA but uses different materials. Here, the material is in powder form, and a laser sinters it layer by layer into the designed shape.

- Selective Laser Melting (SLM)

Here, instead of sintering the powdered material, a laser melts it all the way in order to shape the needed design.

- Digital Light Processing (DLP)

This technology is very much like the SLA, with one very big difference – the source of light. Unlike the laser used in SLA, here we have a projector, and mirrors control its trajectory.

- Electronic Beam Melting (EBM)

This technology is very similar to SLM, with a significant difference in the source of heat – the EBM uses an electron beam instead of a laser, as used in SLM, to melt the materials. It’s important to note that both technologies have enough power to melt even powdered metal.

- Laminated Object Manufacturing (LOM)

Here the layers of material are fused together, each of them coated in the adhesive with heat and pressure. Then the object is cut into a designed shape with a knife or laser. This method makes 3D printing a very rapid process.

3D Printing Process

As we talked about the different technologies, it’s no doubt hard to understand for those people who are far from engineering and manufacturing and looking to get a 3D printer for their kids on Christmas. Of course, all the technologies mentioned above are mostly for production purposes. However, the process of creating an object with a 3D printer is very much the same whether you need to use it to print car parts or a vase for your living room.

Here are the main 3 steps that you need to take to create an object using a 3D printer:

- Design – Here, you need to design your object and transfer it into a CAD format, so the printer can then use it to print the object. The software is widely available both in paid and free formats, and some are even there for you to work online through a website.

- Printing – Here, you need to feed the digital design to the 3D printer and choose the materials you want to use to print the object. There is a wide variety of different ones, from plastics to ceramics, metal and wood.

- Polishing – This is the final step in the process of 3D printing. As soon as your object is printed, now you need to test it and polish it before you can present it to anyone – your family or clients, what have you. Here you can either paint, sand or give other finishing touches to your product.

3D Printers and Types

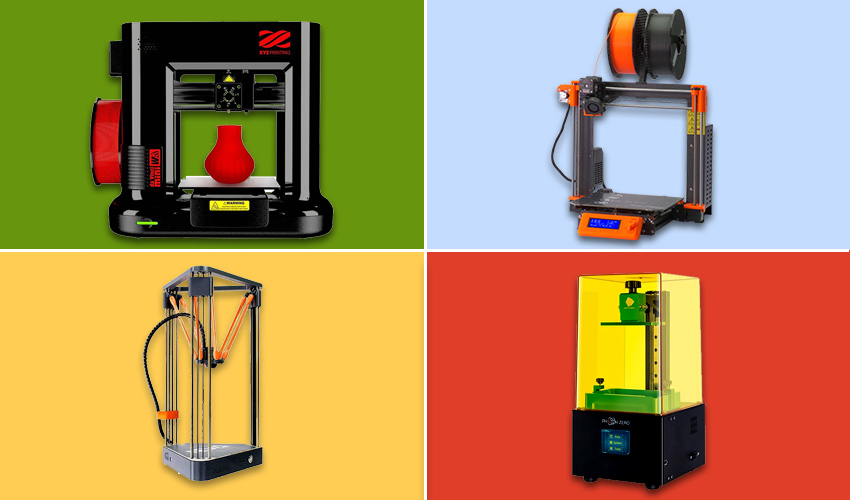

Above, we have talked in length about the different printing technologies, and there are as many different types of 3D printers as there are different technologies.

Different ones are used for different things, in a variety of industries, as each uses a method and material beneficial and applicable for one or another industry.

For example, EMB technology is widely used in manufacturing biomedical prosthetics and lightweight components for the space shuttles aerospace industry. But it will hardly be used in manufacturing clothes or footwear.

The most common in-home 3D printers are the FDM one, as it’s the most simple, is compatible with a variety of filaments, is pretty straightforward in use, and won’t cost you a fortune to purchase.

Plus, it’s more or less safe to have around children, of course with adult supervision only, and won’t take up too much space on your desk or in the garage.

SLA printers are the second most popular 3D printers for homes and classrooms. However, here you are more constricted in the matter of how big of an object you can make, by the size of the printer itself, and you need to operate it in a very well ventilated space, or outside, as the 3D printer will emit a bit of odour while printing.

3D Modelling Process

When it comes to modelling, there are a lot of ready to go models available online. There are many libraries where you can sign up and download as much design as you want for your 3D printer.

In case you want to create your own, then you need to go through some steps to make sure your design doesn’t have flaws, and you can have it in the needed format for the 3D printer to be able to read it and then print the object.

- Create a 2D model of the object (digital or otherwise)

- Extract a 3D model from a 2D file

- Prepare the model

- Export it in a 3D format to use it later on in 3D software

- Scale and adjust the design in 3D software

- Download the ready model to feed it to the 3D printer.

Above is the overview of what you need to do to create a 3D model of your choice, in case nothing that is available online is not a suitable option for you.

3D Printing Accessories: Filament and 3D Pen

As we have mentioned earlier, there are lots of materials used in 3D printing, which is called a filament, in other words.

There are the most common plastic ones – ABS, PLA, PVA, HIPS, PETG, TPE/TPU/TPC, Nylon and much more. You can create anything you want, from Legos to shows and gloves.

There are also some not so common filaments, like wood, metal, wax, ceramics and such. These are more expensive and harder to get. Plus, not all machines are compatible with such filaments. Before purchasing a 3D printer, be sure to investigate what kinds of filaments you can use with it and how much they cost.

Some of these plastics are food safe, like PLA, PP, Nylon-6 and PET, as well as some brands of ABS. However, in case you need to put them into a dishwasher, do not print anything with PLA, PET and Nylon, as they soften in high temperatures.

The cost of these filaments also varies, the eco-friendly and food and child safe ones are naturally on the higher end of the spectrum, but the average price would be about £20 per kg.

In case you want to test out how you feel about a 3D printer in your home or want to make a relatively inexpensive gift for your kid, who might get tired of a 3D printer anyway, a 3D pen might be your best choice!

It’s a small device that will 3D print writings, small objects and is very easy to use. Even your 10-year-old will have loads of fun making school projects with it, and maybe even create fun objects for you and your family, like coasters, magnets and so on.

3D Printing Apps

There is a lot of both paid and free software available for 3D printing, as it grew more in popularity.

Moreover, there are also a lot of apps that will help you master the 3D printing process and make it easier and more fun.

There are a lot of them that are both available for Android and iOS, and some that are only for one or the other.

The most popular one of them would be the Tinkerplay, which gives clear and easy instructions to follow to create the 3D model. Plus, its UI is very intuitive with lifelike simulations.

Other famous ones include Blokify, MakerBot Mobile, Thingiverse, Morphy and Autodesk 123D.

Applications of 3D Printing

As we have mentioned before, 3D printing has become popular with industries much sooner than it began to be accessible and available for household use.

There are many industries that have been using 3D technology to create an easier or maybe cheaper manufacturing line and automating their processes.

Here are the most common uses of 3D technology in manufacturing by industries.

Architecture & Construction

Back in the olden days, architects used to create their models of cardboard, paint them and maybe even make it a family pastime.

However, today all that’s behind us, with a 3D printer at hand. The process is much faster and efficient. Plus, no more arts and craft supplies clotting the office or the home office.

However, 3D printing technology has gone way further than just being a handy model building equipment. It might sound like something futuristic, but there are buildings now being built with 3D technology.

The first commercial 3D printed construction was a pedestrian bridge over the stream in the Park of Madrid that opened to the public in late 2016.

Less than a year later, the first 3D printed building was built in 2017 in Copenhagen, Denmark. At the moment, the biggest 3D printed building, which is registered in the Guinness Book of World Records, is 9.5 meters tall and has a space of 640 square meters.

Automotive

Like any other, the automotive industry has adopted 3D technology and has been using it for some time now. As 3D printing doesn’t only mean plastic, but metal too, there have been many items produced in this manner, from end-use parts and spares to fixtures and tools.

Plus, this technology has given an opportunity to put the warehouses and stocking problems behind, as on-demand manufacturing is a primary source of such items. In case you need an item, you make it. If not, then don’t.

With the rise of electric cars and motorcycles, additive manufacturing has become a huge part of their production. There are even some that are fully 3D printed. For example, the use of 3D printing technology in the manufacturing of BigRep’s electric motorcycles has reduced their production line to 12 weeks.

Aerospace & Aviation

As we see Elon Musk building spaceships that can return safely to Earth and be reused, it would be silly to assume that one of the greatest visionaries of the modern-day doesn’t use a new technology that can do so much more than traditional manufacturing, at the same time reducing costs and introducing new materials.

#d printing made it possible to introduce new materials that are reducing weight and at the same time are increasing their durability. These materials are widely used in both aerospace and automotive industries to create parts of the aircrafts like fuel nozzles and some inside parts.

Plus, there are currently rocket engines and parts are being partially and sometimes fully built using 3D technology. As the benefits of additive manufacturing are undeniable, the industry welcomes the possibility of less material waste, higher production speed and better products as an outcome.

There are also some “crazy” ideas floating, like those that propose self-replicating 3D printers that can even process soil on the Moon. This, of course, would make the colonisation and exploration of the moon very efficient, but as of today remains a very bold idea from the researchers of the University of Ottawa. We will probably see something similar being developed soon enough. 3D printing software and technology has made a huge leap of advancement in the past few years.

Racing

When it comes to racing, even the millisecond can make a huge difference in determining the winner. Thus, 3D printing can come in very handy in order to create the best car on the track by making the parts of the car more durable and lighter at the same time with innovative materials, and as a consequence providing it with greater speed.

There are also advantages for racers when the speed of wheel changing is increased, and that’s also when additive manufacturing can come in handy, creating tools necessary for a quicker process.

Medical

The medical industry has been one of the first ones to embrace 3D printing technology. There are so many different applications here that it’s hard to name them all.

First and foremost, additive manufacturing has revolutionised the dental industry. From night guards and aligners to fixing broken teeth and floss assistance – there is nothing that 3D printing can’t help you with. It also helps with creating a mould for further carvings of the ceramic crown or creating dentures. 3D printing has sped up this process, making it much cheaper.

3D printing has also revolutionised the manufacturing of prosthetics, using much lighter and durable materials. Anything from hearing aids to a prosthetic hand or foot – you name it, 3D printer will make it.

Moreover, additive manufacturing has been a great aid in creating eyewear from new materials that can bend and not break, providing patients with the longevity of the glasses and the convenience of not having to change them so often or be very gentle with them.

Another application of 3D printing technology in the future may be donor organ 3D printing. The idea is to take a tissue sample and create a fully functional organ using additive manufacturing. This technology is being developed as we speak, so it can soon be our reality.

Jewellery

This industry has also been very fond of 3D printing, as it’s used to create the designs and moulds for further carving it from the metal. 3D prototyping has made the mass production of jewellery much more efficient and rapid.

The most common material used for designers within jewellery is metal. 3D Printing materialises the following materials to develop its products: Brass (Gold, colour and PU plating), Silver (Gloss and high gloss, satin, sandblasted and antique) and Gold (14k or 18k and polishing).

Consumer Products

Nowadays, we can find more and more products being 3D printed for mass production. Such things include clothes, footwear, eyewear, jewellery, accessories. The list goes on and on.

There are many famous brands, such as Adidas, that are now mass producing sneakers that have been 3D printed using recycled plastic.

There are also items of home decor, like reproductions of famous paintings, that you can purchase for your home that were 3D printed. They not only give you the image but also texture, making them the most realistic reproductions.

3D Printing In Education And At Home

It is undeniable that the future has a lot in store for us when it comes to using 3D printing technology. Thus, we need professionals that understand this technology, know how to operate it and are able to develop it further to accommodate the needs of tomorrow.

Hence, it’s very important to introduce this piece of technology in the classrooms and get the kids and students excited and interested in it. It is also crucial to teach them how to use it and all the much needed and potential applications of it.

In the medical and science faculties of universities, a 3D printer should be an inseparable part of their learning process, as that’s the equipment that they will use in their everyday work tomorrow.

You can also get a 3D printer for your home, in case you are into technology and want to get your kids fired up about it too. There are many items of home decor you can make with it like vases, keychains, picture frames, toys, oven mitts and so on.

There are really no limits to the imagination when it comes to the minds of our children and what they want to play with.

If your kids are crafty and like to make things on their own, then a 3D printer at home can be a valuable asset for their development and a great tool to make personalised presents and toys for the whole family.

How to choose a 3D printer

Now that we know pretty much anything there is to know about 3D printing, let’s see what criteria you need to take into account, in order to pick a perfect 3D printer for your needs.

So let’s start from the basics. Ask yourself several basic questions:

- What do I want to print?

- What type of 3D printer should I buy?

- What features should I look for?

- What materials do I need to print with?

- How much should I spend?

There are many more questions that need to be answered for the full picture, however, these are probably the most fundamental ones, so you can get an idea of at least where to start.

Consider Application

First and foremost you need to answer yourself, what will be the main application of the 3D printer? D

Do you need it for work, education, starting a business, hobby, for your kids?

As soon as you decide on the application, you can then start searching 3D printers in that category, and consider other features.

There are details associated with each application.

For example, 3D printers for kids are very limited in their printing capabilities and filament choice, as they need to be as safe as possible for the child’s use with minimum supervision.

On the other hand, professional 3D printers can be very expensive and massive in size, and might simply not have enough room or budget to be able to purchase them. They are also very particular with compatible filaments.

You might have a question about what style of 3D printer do I need? The answer to this question also derives from its application.

As you already know there are various types of 3D printers, each approaching the printing process in its own, unique way.

Thus, you need to get the one that will help you print exactly what you need in the most convenient, fastest and cost-effective manner.

Consider Features

There are several very important features you need to look for in a 3D printer, as soon as you decide on your application.

Above all, it’s the printing size.

The printing size may limit your printing options and creativity. However, if you know exactly what you need it for, and are not planning to diversify, even a small printing size can suffice.

For instance, if you are a dental technician, and will be printing dental moulds for your patients, you probably are not going to need a huge printing size.

However, if you want to get the 3D printer to experiment with different shapes and sizes at home, creating items for home decor, vases and so on, a small printing size will significantly reduce your creative capacity.

One more question you might have is do I need multiple filament support?

Again, this feature matters a lot for creative freedom, and if you need to create multi colour objects.

In such a case, yes, you should definitely consider getting a 3D printer that can support any need you might have.

Still, if you know exactly what you will be doing, and multicolour objects are in no way on the list of your priorities, it’s better to get a simpler model that gets the job done, instead of looking for extras.

In general, the filament types are an important feature to take into account. There are somewhat universal 3D printers out there, that have a wide range of filament support, and there are those that are limited in their filament compatibility.

Again, everything depends on the application.

Consider Budget

Budget is another very important point to take into account when choosing a 3D printer.

As we have already discussed, beginner and professional 3D printers differ, as well as their prices.

You can find a 3D printer for as little as $50 and as much as $60.000.

Naturally, those that are on the high end of the spectrum are mostly highly professional ones, used in manufacturing and global industries.

When it comes to personal use, start-ups and such, most probably the one you chose will be in the range of $250 – $1000.

This will be a decent quality and feature set machine, with high performance and ease in use.

Remember, not to go for the cheapest option, as the quality won’t stand the test of time. Plus, the end product most probably won’t satisfy you.

Keep in mind – buy cheap, buy twice!

Why You Should Choose Us

As you can see, 3D printing is an amazing piece of technology that is now available for us at home, and we should no doubt teach our kids the new tech as soon as possible, as it’s going to be even more widespread and popular in the future.

There are many different shops where you can purchase a 3D printer for home, but here are some reasons why you should choose us.

- We put our clients in the centre of all our activities and guarantee 100% satisfaction every time you shop with us.

- 3D Printer World is a specialised 3D printer shop UK market has to offer and is one of the best ones out there with a set of great services to go with the wide selection of high-quality 3D printers and best prices.

- We offer free delivery around the UK, as well as a warranty on all of our machines. We also got your back with 24-hour customer support and a 30-day money-back guarantee, which just shows how customer-centric our company really is.

- Plus, our very user-friendly website and easy navigation interface will make a shopping experience pleasant and stress-free.

To Sum Up

OK, so what do we know so far?

- 3D printers are the present and the FUTURE, and slowly but surely becoming a part of our lives.

- There are many different 3D printing processes that will accommodate basically any need.

- 3D printing can be used in nearly any industry to automate, innovate or scale.

- You know the exact steps to choose the 3D printer to perfectly fit your needs.

Now you can begin your 3D printer journey with ease and pick the one that will fully satisfy your needs and expectations.